Innovation-Driven Technology-Oriented

Since its establishment in 2003, Zhejiang Jindao Technology Co., Ltd. has been committed to the R&D and innovation of industrial vehicle transmission systems. Guided by the philosophy of “Technology Drives the Future”, the company has continuously invested in technology and strategic industrial deployment, establishing itself as a highly competitive innovator in the industry.

-

Patent Achievements

The company has obtained more than one hundred independent intellectual property rights, including multiple invention patents.

-

R&D Platforms

Jindao operates a range of provincial and municipal-level technology innovation platforms, including a Provincial High-Tech Enterprise R&D Center, Corporate Research Institute, Corporate Technology Center, Shaoxing Doctoral Innovation Workstation, Corporate R&D Center, and Industrial Design Center.

-

R&D Investment

With continuous annual investment in R&D, the company upgrades existing products, actively develops new ones, and consistently explores cutting-edge technologies in the industry.

The company-led electro-hydraulic transmission project was selected as a National Torch Program Project; multiple in-house R&D projects have been recognized as Provincial New Industrial Products and High-Tech Products; the independently developed SCQ35 Wet Drive Axle was recognized in 2024 as the First Set of Key Equipment Product in Shaoxing’s Equipment Manufacturing Sector.

Core Technological Advantages

The company has been deeply engaged in the field of industrial vehicle transmissions, always adhering to the principle of “innovation-driven,” placing strong emphasis on R&D activities, and achieving remarkable results:

The company has developed a complete set of core technologies around forklift transmissions, including Noise, Vibration and Harshness (NVH) analysis and control, gear optimization design, electro-hydraulic control (TCU), and mechatronic control technologies.

The company has established a well-structured and comprehensive product portfolio of transmission devices and components, featuring strong core competitiveness. Its core products cover the full technological spectrum of mechanical transmission, hydrodynamic transmission, and electric transmission.

The product portfolio includes gearboxes, final reducers, axle housings, steering gears, and other component modules.

-

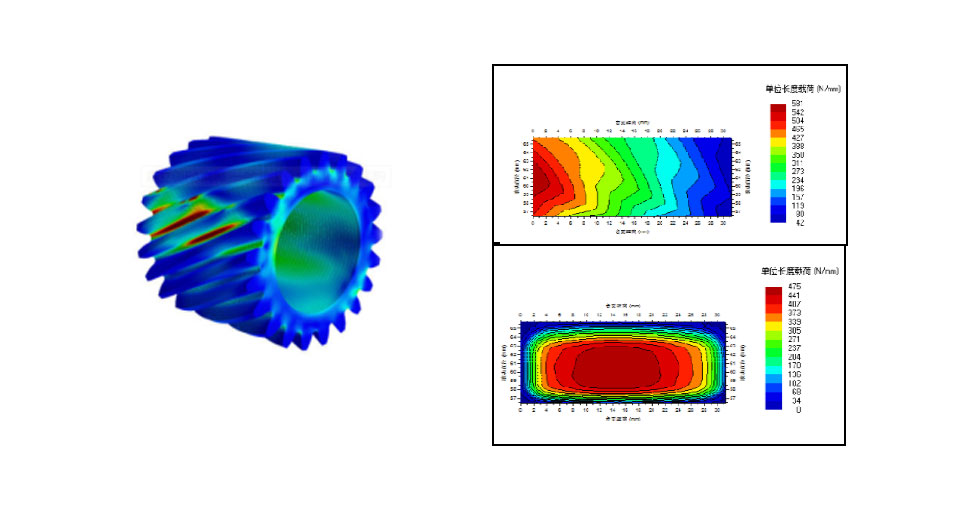

Microscopic gear analysis and research technology

-

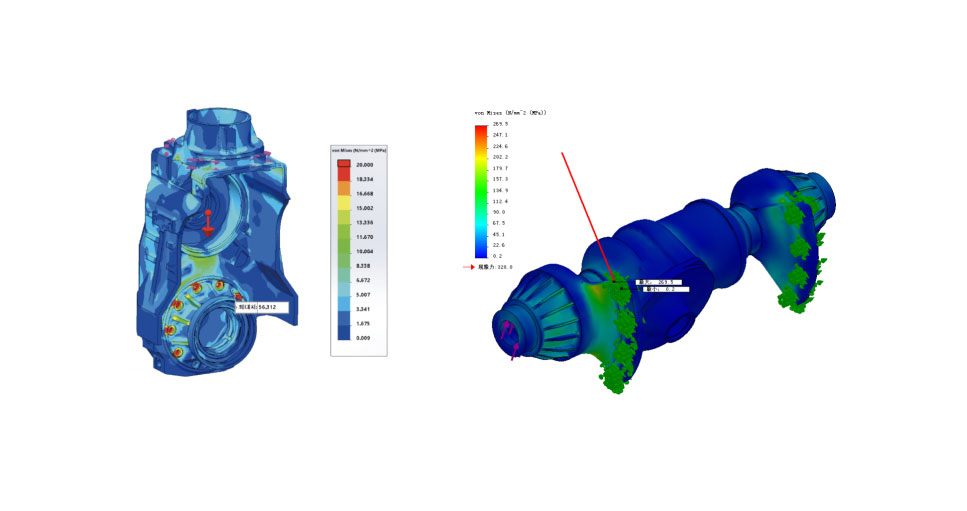

Finite element analysis and research technology

-

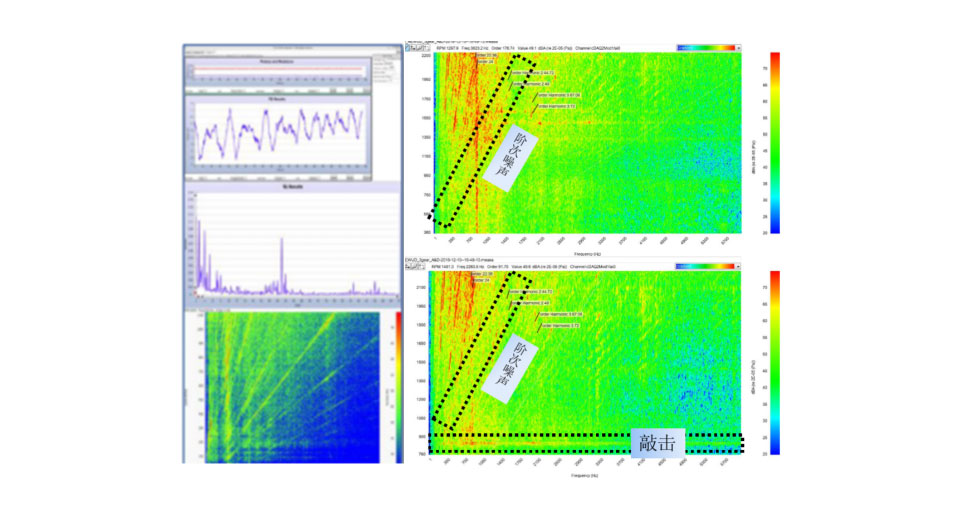

NVH analysis and research technology

-

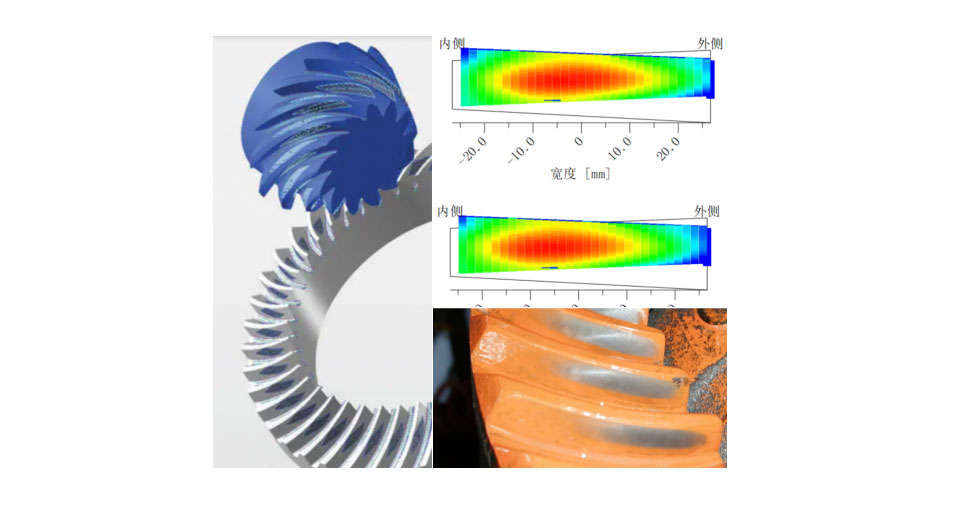

Hypoid gear analysis and research technology

How Do We Drive Innovation?

As the core power transmission component of industrial vehicles, forklift transmissions directly impact the efficiency, reliability, and intelligence of the entire vehicle. To continuously and systematically promote innovation, the company has built a four-in-one innovation engine consisting of technological breakthroughs, ecosystem collaboration, scenario-driven development, and organizational activation.

-

Technological Breakthroughs: From Materials to Intelligent Control

-

Ecosystem Collaboration: Breaking the Innovation Silos

-

Scenario-Driven: From General to Vertical Fields

-

Organizational Activation: Cultivating the Soil for Innovation

-

Innovation Value Closed-Loop: From Technology to Business Optimization

In the process of R&D and innovation, we have carried out the following explorations and practices: high-strength lightweight alloy materials, gear topology optimization, integrated modular design, multi-speed electric drive transmissions, intelligent control empowerment including predictive shifting strategies and digital twin operation & maintenance.

We work in close collaboration with universities, partner customers, research institutions, and end users, establishing an open innovation platform and R&D network with a four-in-one structure, thereby enhancing innovation value across multiple dimensions.

We extend from general application scenarios to extreme working conditions, providing customized overall transmission system solutions for diverse application needs. Through human-machine interaction upgrades, we integrate adaptive learning transmissions with acoustic comfort optimization, enabling automatic matching of smoothness curves while effectively eliminating noise in specific frequency ranges.

We have established an agile development mechanism, implemented a maker group-based working method, and set up a rapid trial-and-error fund for high-risk technology pre-research.

We have introduced an anti-fragility talent cultivation mechanism, built a cross-disciplinary capability matrix for engineers, and promoted an on-site immersion working method for R&D personnel.

We have established a digital R&D foundation, comprehensively integrating modular knowledge bases and AI-assisted design.

R&D Culture

We believe that every idea deserves to be ignited. Jindao Technology fosters an open and inclusive culture of innovation, encouraging employees to constantly challenge themselves and collectively drive the company’s technological advancement.

-

Internal Innovation Incentives

We have established dedicated reward mechanisms to encourage employees to propose feasible technical solutions.

-

Cross-Department Collaboration

R&D, production, and marketing teams work in close collaboration to ensure that technical solutions meet real-world needs.

-

Continuous Learning

The company regularly organizes technical sharing sessions, inviting senior industry experts and in-house R&D staff to exchange insights on new technologies.

The Future of Jindao

Jindao Technology will take R&D and innovation as its core driving force, advancing multi-dimensional development in new energy and intelligent transmission systems, with the goal of becoming a global technology leader in industrial vehicle transmission systems.

In the future, we will continue to increase R&D investment, accelerate the industrialization of technological achievements, and create greater value for our customers.