ZhejiangJindao Technology

About us

Since its establishment in 2003, Zhejiang Jindao Technology Co., Ltd. has been dedicated to the industrial vehicle transmission industry, specializing in the R&D, manufacturing, and sales of transmissions for forklifts and other industrial vehicles. In April 2022, the company successfully went public on the Growth Enterprise Market of the Shenzhen Stock Exchange (A-shares), with stock code 301279.

With over 20 years of deep expertise in industrial vehicle transmission systems, the company has mastered the core technologies of various forklift transmissions, wet drive axles, and related products, holding more than 100 independent technology patents, including multiple invention patents. Jindao is recognized as a National High-Tech Enterprise and a Zhejiang Province Small and Medium Technology Enterprise. Leveraging multiple provincial and municipal-level technology innovation platforms—such as the Provincial Enterprise R&D Center, Corporate Research Institute, Corporate Technology Center, Shaoxing Doctoral Innovation Workstation, Corporate R&D Center, and Industrial Design Center—the company has developed cutting-edge products including high-voltage lithium battery transmissions, intelligent floating transmissions, and integrated electrified systems, forming a complete system capable of serving global forklift OEM customers.

The company provides comprehensive transmission system solutions for industrial vehicles. With advanced technology, reliable product quality, and dependable after-sales service, Jindao has earned the trust of both domestic and international forklift OEMs, maintaining long-term, stable partnerships with major Chinese forklift manufacturers such as Hangcha Group. In recent years, the company has actively expanded into international markets, successfully entering the supply chains of top global forklift OEMs including Toyota, Mitsubishi Logisnext, KION Group, Jungheinrich, Doosan, Clark, Hyundai, and Hyster, making Jindao one of the few Chinese companies integrated into internationally renowned forklift supply chains.

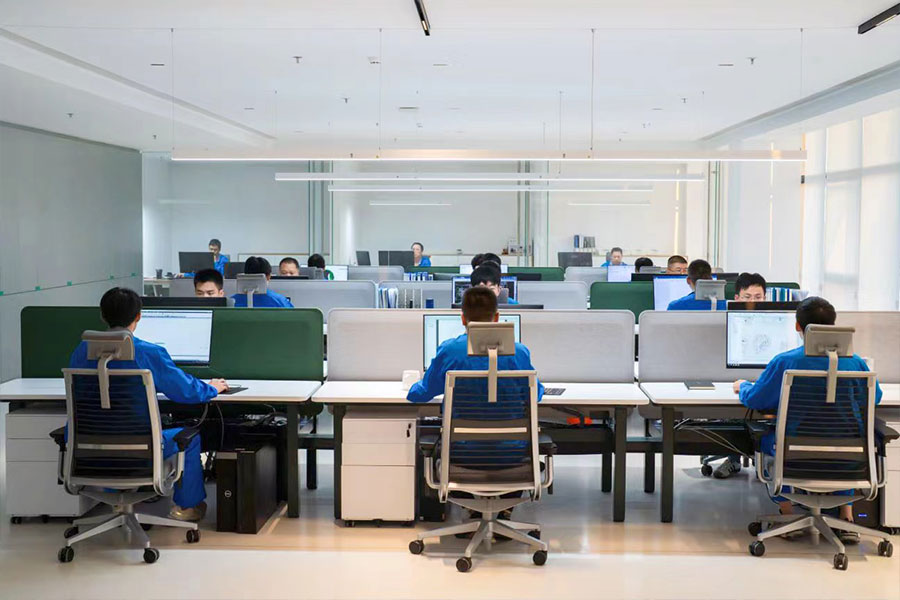

Jindao Technology has invested in a new energy logistics transmission machinery project covering over 120,000 m², establishing a production base that integrates automation, intelligence, and digitalization, aligned with international professional standards in the industry. The facility aims to accelerate the industrialization and large-scale production of specialized logistics transmission devices, further enhancing the company’s production and technological innovation capabilities, improving overall industry competitiveness, and better meeting the demands of international clients.

Guided by the vision of becoming a “world-class competitive expert in transmission systems”, and adhering to the management philosophy of “innovation-driven, customer-focused”, the company implements a sustainable and internationalized development strategy. Upholding the corporate spirit of “integrity, people-oriented, pioneering innovation, and teamwork”, Jindao strives to create value, give back to society, and achieve its goal of becoming a global leader in forklift transmissions.